The thermomechanical treatment

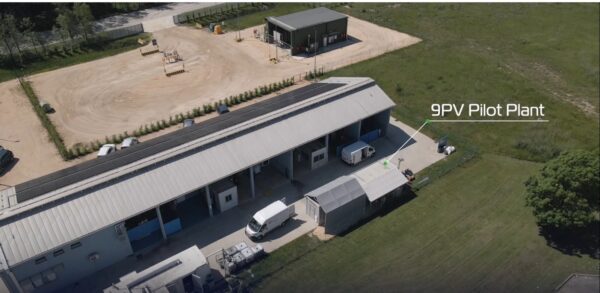

The experimentation began in 2020 with a EIT RawMaterials Booster project that started the design of 9-Tech’s experimental photovoltaic panel recycling plant.

The plant, initially designed and built in 2020 and then significantly modified and expanded in subsequent years, operates thermal and mechanical treatment of the End of Life PV panels to recover their component raw materials.

The technology is protected with several European patents and uses a much more efficient and advantageous process than the previous process studied during the ReSiELP project.

The 9PV plant is hosted at Veritas Group’s Green Propulsion Lab, a platform funded by the Ministry of Environment for the revitalization of Porto Marghera in Venice, which studies green technologies and hosts several innovative start-ups such as 9-Tech. We also talk about it in this interview.

The pilot plant was authorized by the Veneto region through Decree No. 183 of July 4, 2022 and has proven a panel treatment capacity of 30kg/h.

Testing began by receiving the first panels to be treated (about 360kg) on November 7, 2022, and since then the actual experimental activity began, which is still ongoing. The plant has already been proved to be extremely energy efficient and capable of recovering pure materials to be reused as secondary raw materials.

Silver recovery

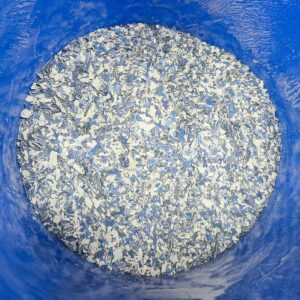

The photovoltaic cells recovered by the pilot plant consist of silicon, aluminum, and silver. Silver is by far the material with the highest specific value within a photovoltaic panel, therefore a treatment has been developed that exploits the mechanical action of ultrasound and reagents with low environmental impact for its recovery.

The patent application for the process was submitted in January 2023.

LThe development of this part of the treatment was carried out thanks to the victory of the InactionESG award from Intesa SanPaolo Vita and Fideuram Vita received in 2022.

See also:

Parsival aims to solve territorial problems relating to the procurement, recycling and reuse of raw materials in RIS areas.

The project to build a 4500 t/year recycling plant of photovoltaic panels in Porto Marghera (Venice)

The project aims to further refine the innovative and sustainable process for recycling end-of-life PV panels by increasing the IRL from 5 to 7.

Discover the other 9-Tech projects for the recycling of photovoltaic panels

European project to study the recycling of photovoltaic panels with the most advanced available technologies