The Parsival project is a two-year RIS Capacity Building project, which began on January 1, 2023 and coordinated by 9-Tech.

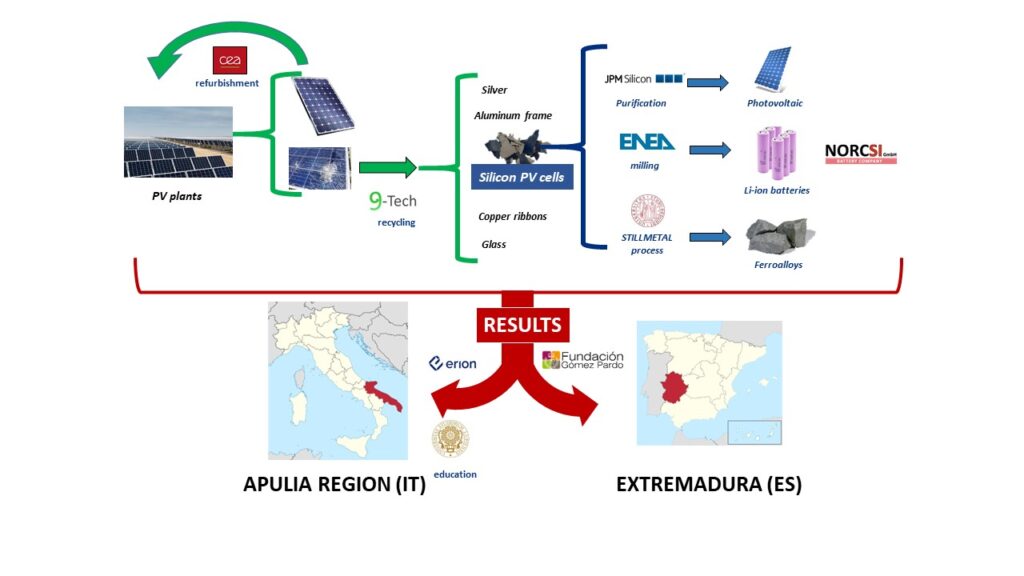

The objective of the project is to mobilize the triangle of knowledge (education, research and innovation) and create a network on a European scale around the challenge relating to the recovery and reuse of materials obtained from end-of-life photovoltaic panels, in particular silicon ( Critical Raw Material).

RIS capacity building projects, in particular, must have as goal the solution of territorial issues about procurement, recycling and reuse of raw materials in RIS (Regional Innovation Scheme) areas.

Apulia is in a RIS area (Southern Italy) and the disposal of end of life panels is an emergin issue:

The project aims to build the framework for refurbishment and recycling facilities for end-of-life photovoltaic panels in these areas. In this way it will be possible to allocate the repairable panels to a second life and the materials, recovered from the no longer reusable panels, to different supply chains. For silicon, three different applications will be studied during the project:

- silicon-based ferroalloys;

- material for battery anodes;

- production of new photovoltaic cells.

The success of the project, which also includes an educational part, may benefit these areas but also other European countries.

Partners of the project

Four partners are involved from four countries (Italy, France, Germany, Spain):

Projects for photovoltaic panel recycling

The innovative process for recovering materials from photovoltaic panels tested on a pilot scale.

The project to build a 4500 t/year recycling plant of photovoltaic panels in Porto Marghera (Venice)

Discover the other 9-Tech projects for the recycling of photovoltaic panels